General New EU project aWISH: automated at-slaughter monitoring of chicken and pig welfare

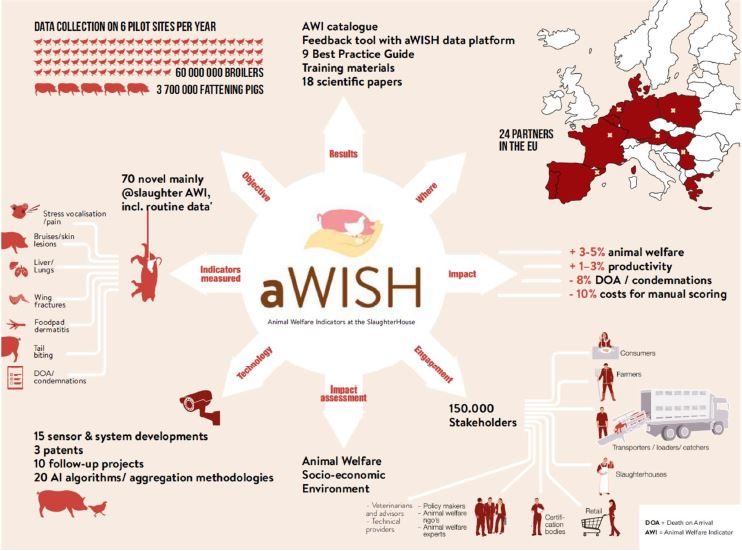

At the heart of the aWISH project (Animal Welfare Indicators at the SlaughterHouse) is the large-scale, automated at-slaughter monitoring of animal-based welfare indicators for quantifying animal welfare status on-farm, during (un)loading, transport and slaughter. Novel sensors and accompanying artificial intelligence decision tools and algorithms will be developed and tested to measure these indicators, so data can be collected continuously and automatically. The aim is then to use this data to give feedback and advice on best practices to those responsible for the chicken and pigs throughout their lifetime (farmer, catching team, transporter, slaughterhouse). This approach will be developed and evaluated in close collaboration with all actors involved, from the livestock farmers up to policy makers and citizens.

The aWISH project is funded by Horizon Europe and will run from 1st of November 2022, for 4 years in total. The project is led by ILVO (Flanders Research Institute for Agriculture, Fisheries and Food, Belgium) and has 24 partners from 13 European countries. At the core of the project are 6 regional chicken and pig production chains or pilots, spread across Europe (FR, PL, ES, NL, AT, RS), where the aWISH developments will be tested and validated.

The project focuses on broiler chickens and fattening pigs for several reasons. Both sectors are very important economic segments of the EU and world food production. However, they also deal with large numbers of animals, that require individual attention to optimize their welfare. Broiler chickens and pigs are the farm animals with the most concerns expressed by EU citizens. Also, on-farm animal welfare monitoring is difficult and time-consuming for these species. With our automated methods concentrated at a central location, which is the slaughterhouse, we can help overcome this challenge. By demonstrating and evaluating the overall concept for these two farm animal types we also believe a spread of knowledge and technologies to other types of meat-producing livestock can be expected, such as cattle, turkeys, or ducks.

aWISH uses a lean multi-actor approach focusing on user acceptability and co-creation with the different stakeholders. The 6 pilots (see map) are led by multi-disciplinary teams and will develop and test novel animal welfare monitoring technologies, collect the necessary animal welfare data in their specific region and test the aWISH feedback tool. Besides this animal welfare assessment, also an environmental assessment will be conducted to detect synergies and minimize trade-offs between animal welfare improvement and environmental impacts. Combinations of innovative animal welfare options with high ecologic efficiency and reduced resource consumption along the whole production chain will be explored. A catalogue of animal welfare indicators will be developed for any stakeholder to use, to assess the welfare of fattening pigs and broiler chickens. Also 9 best practices guides will help external actors to deploy the aWISH technologies and feedback tool and improve animal welfare across Europe.

ILVO, Flanders Research Institute for Agriculture, Fisheries and Food, is coordinator of the aWISH project and thus responsible for amongst others the management and quality assurance of the project. ILVO is also involved in other work, and especially in the animal welfare assessment and improvement on farm and chain level, where the impact of the automated monitoring and feedback system will be analyzed for farmers, loaders, transporters and the slaughterhouse in the different pilots.

For more information contact the coordinating team | ILVO | awish@ilvo.vlaanderen.be or national contact | ILVO contact persons